Sharpen chisels and plane knives to perfection.

For woodworkers, leatherworkers, designers, craftspeople, re-enactors,

technicians, amateurs, and professionals…

For woodworkers, leatherworkers, designers, craftspeople, re-enactors,

technicians, amateurs, and professionals…

You buy chisels or planes, but your new tool dulls very quickly.

No matter how many times you resharpen or hone it,

it dulls again and again, or even loses its sharpness altogether. Why is this?

This kind of approach is very demotivating in the long run, and

most people quit after a while.

There are several reasons why this happens repeatedly.

No matter how many times you resharpen or hone it,

it dulls again and again, or even loses its sharpness altogether. Why is this?

This kind of approach is very demotivating in the long run, and

most people quit after a while.

There are several reasons why this happens repeatedly.

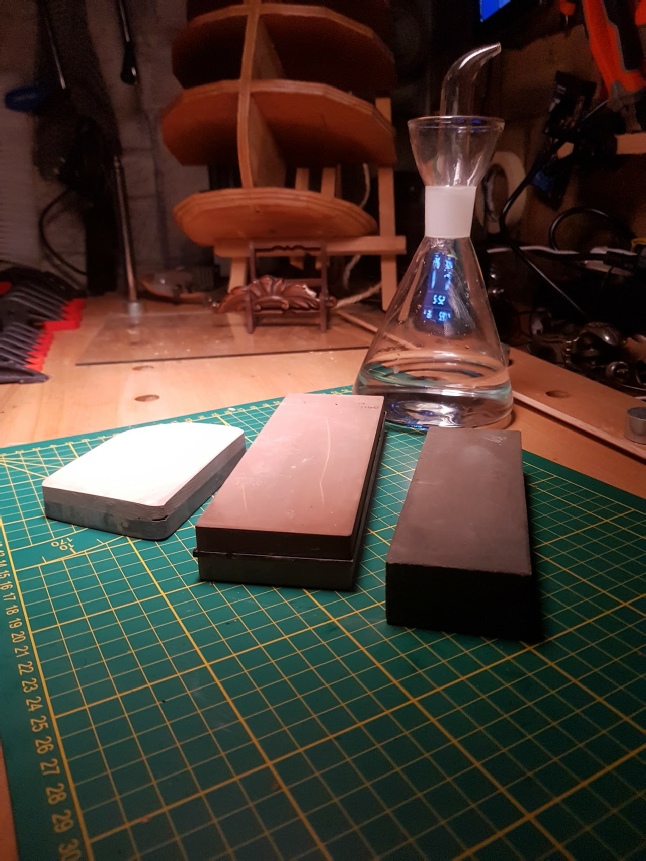

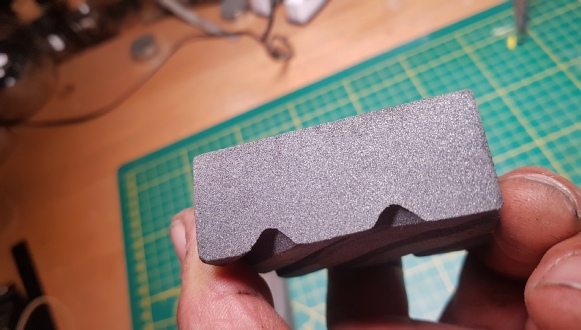

Wet sharpener with 2000 grit. This stone can be smoothed to a level comparable

to a whetstone with 8000 grit or higher.

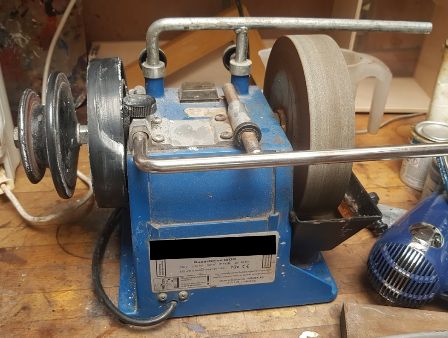

Image above: Electric sharpening stone that can rotate in both directions

and its speed is also adjustable.

The left wheel has a leather strap for polishing, and the right is a wet sharpening stone with 2000 grit

with a removable water tray, etc.

to a whetstone with 8000 grit or higher.

Image above: Electric sharpening stone that can rotate in both directions

and its speed is also adjustable.

The left wheel has a leather strap for polishing, and the right is a wet sharpening stone with 2000 grit

with a removable water tray, etc.

Learn to sharpen your chisels and planes with the right tools and discover a new joy and true pleasure of truly ultra-sharp tools…

If you do it correctly, you can easily shave your hair with a chisel or plane knife,

without scratching your skin...

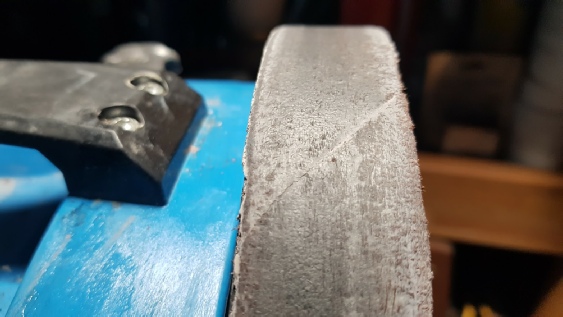

Learn to rough up your wet grinder to make quick adjustments to the tool.

Afterward, make your wet grinder very smooth again so that whetstones are no longer necessary.

If your wet grinder is properly smoothed, you'll notice that the sharpened area looks like it's chrome-plated.

This way, you can save on very expensive whetstones and they'll last a lifetime.

You can continue to use your whetstones if you want to sharpen without using electricity.

If you can't find suitable whetstones quickly enough, you can also use very fine sandpaper for metal.

Make sure you can access at least 2000 grit or higher.

For a fine finish, use 10,000 grit or higher.

You can also use liquid polish instead of water on your sandpaper. Preferably a polishing agent where the granulate becomes finer the longer you polish.

The fewer scratches on your polished surface, the sharper your tool will be.

If you do it correctly, you can easily shave your hair with a chisel or plane knife,

without scratching your skin...

Learn to rough up your wet grinder to make quick adjustments to the tool.

Afterward, make your wet grinder very smooth again so that whetstones are no longer necessary.

If your wet grinder is properly smoothed, you'll notice that the sharpened area looks like it's chrome-plated.

This way, you can save on very expensive whetstones and they'll last a lifetime.

You can continue to use your whetstones if you want to sharpen without using electricity.

If you can't find suitable whetstones quickly enough, you can also use very fine sandpaper for metal.

Make sure you can access at least 2000 grit or higher.

For a fine finish, use 10,000 grit or higher.

You can also use liquid polish instead of water on your sandpaper. Preferably a polishing agent where the granulate becomes finer the longer you polish.

The fewer scratches on your polished surface, the sharper your tool will be.

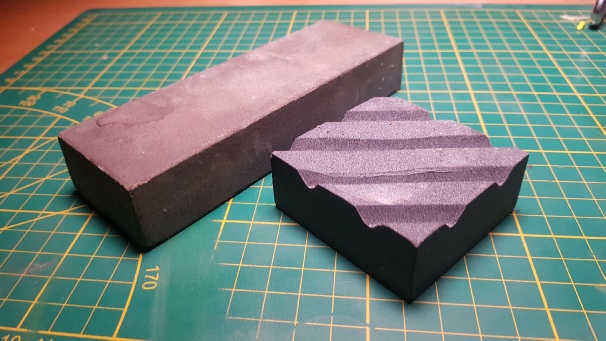

The most common whetstone has a visible grit that is too coarse.

However, these are far too coarse, and you shouldn't use them dry either...

Not even for a short time, and yet it's still done, but it's still wrong.

However, these are far too coarse, and you shouldn't use them dry either...

Not even for a short time, and yet it's still done, but it's still wrong.

These coarse stones with grits 80 and 400 function more like coarse or smooth files and are best not used for chisels,

planes, kitchen knives, drills, scissors, etc.

They can be used to quickly file away a lot of metal.

For example, very deep cuts from axes or sawdust, etc.

But to get your chisels, plane knives, etc., ultra-sharp, you really shouldn't use them; you need a much finer grit for that.

Whetstones shouldn't make deep scratches in the metal.

If your wet grinder already has a grit of 2000, you'll need a higher grit of at least 3000 or higher after sharpening, and finish up to a grit of 8000.

But you can also smooth your wet grinder much more and then use leather and liquid polish. You'll rarely, if ever, need your whetstones anymore.

They can still be useful if you want to sharpen without using electricity.

planes, kitchen knives, drills, scissors, etc.

They can be used to quickly file away a lot of metal.

For example, very deep cuts from axes or sawdust, etc.

But to get your chisels, plane knives, etc., ultra-sharp, you really shouldn't use them; you need a much finer grit for that.

Whetstones shouldn't make deep scratches in the metal.

If your wet grinder already has a grit of 2000, you'll need a higher grit of at least 3000 or higher after sharpening, and finish up to a grit of 8000.

But you can also smooth your wet grinder much more and then use leather and liquid polish. You'll rarely, if ever, need your whetstones anymore.

They can still be useful if you want to sharpen without using electricity.

Simply sharp is not the same as ultra sharp…

The easiest whetstones to find in stores are often the coarse blue stones with visible pores between the grains. These are already much too coarse for chisels and plane knives, but many people don't realize this...

Chisels and plane knives, which are also the easiest to find, are made of a metal that's too soft,

and that's also where many people make the mistake...

Hone your sharpness to an ultra-sharp edge with diamond whetstones just won't work.

Diamond has an incredibly hard grit and is therefore definitely not suitable for getting the soft metal ultra-sharp. You'll always have scratches from the diamond on your edge, which will make it more likely to be serrated, but you won't see this with the naked eye...

Most diamond whetstones only go up to grit 3000.

They can certainly be used to level your wet grinder or whetstones.

It's a real nightmare for the cutting edge of your tool,

especially if you want it ultra-sharp...

Depending on the coarseness of the grit/granulate and the hardness, this quickly leads to a serrated edge.

Diamond granulate that comes loose from the stone doesn't get any finer, and always results in a serrated cutting edge.

Chisels and plane knives, which are also the easiest to find, are made of a metal that's too soft,

and that's also where many people make the mistake...

Hone your sharpness to an ultra-sharp edge with diamond whetstones just won't work.

Diamond has an incredibly hard grit and is therefore definitely not suitable for getting the soft metal ultra-sharp. You'll always have scratches from the diamond on your edge, which will make it more likely to be serrated, but you won't see this with the naked eye...

Most diamond whetstones only go up to grit 3000.

They can certainly be used to level your wet grinder or whetstones.

It's a real nightmare for the cutting edge of your tool,

especially if you want it ultra-sharp...

Depending on the coarseness of the grit/granulate and the hardness, this quickly leads to a serrated edge.

Diamond granulate that comes loose from the stone doesn't get any finer, and always results in a serrated cutting edge.

To hone with the right whetstone, a few backward pulls are more than enough,

The metal being circulated is very soft, never forget this.

Round circles or forward motions with the cutting edge for honing are wrong.

The softer the stone, the faster you'll dent it, causing the tip/edge of your tool to become convex or rounded.

Sharp is not the same as ultra-sharp.

With ultra-sharp tools, you need much less force for planing, chopping, chipping, etc.

Dry grinding with coarse machines that produce orange sparks is a bad idea...

It belongs in the category of "brute grinding," instead of "brute"...

It burns your metal, making it even softer than before, so it dulls even faster.

Yet, those dry sharpeners are sold everywhere, behind every corner...

Those dry knife sharpeners aren't good either, and they ruin your tools...

You won't be able to make ultra-sharp tools with those things.

How do you determine which whetstone and metal type you need?

The softer the metal, the finer and softer the whetstone you need...

The harder the steel, the harder the whetstones you need.

Hard grit doesn't necessarily mean coarser stones...

Everything also depends on the type of wood or material you want to work with,

whether it's for short-term or long-term use, etc.

For long-lasting sharpness, you need a slightly harder metal,

especially if you sometimes switch from soft to harder materials, etc.

Make a good choice when purchasing tools and whetstones, or very fine sandpaper,

for long-lasting sharpness.

With a little experimentation, you'll quickly discover what's best for your tools...

If you're having trouble, need help or advice, please contact us to schedule an appointment.

The metal being circulated is very soft, never forget this.

Round circles or forward motions with the cutting edge for honing are wrong.

The softer the stone, the faster you'll dent it, causing the tip/edge of your tool to become convex or rounded.

Sharp is not the same as ultra-sharp.

With ultra-sharp tools, you need much less force for planing, chopping, chipping, etc.

Dry grinding with coarse machines that produce orange sparks is a bad idea...

It belongs in the category of "brute grinding," instead of "brute"...

It burns your metal, making it even softer than before, so it dulls even faster.

Yet, those dry sharpeners are sold everywhere, behind every corner...

Those dry knife sharpeners aren't good either, and they ruin your tools...

You won't be able to make ultra-sharp tools with those things.

How do you determine which whetstone and metal type you need?

The softer the metal, the finer and softer the whetstone you need...

The harder the steel, the harder the whetstones you need.

Hard grit doesn't necessarily mean coarser stones...

Everything also depends on the type of wood or material you want to work with,

whether it's for short-term or long-term use, etc.

For long-lasting sharpness, you need a slightly harder metal,

especially if you sometimes switch from soft to harder materials, etc.

Make a good choice when purchasing tools and whetstones, or very fine sandpaper,

for long-lasting sharpness.

With a little experimentation, you'll quickly discover what's best for your tools...

If you're having trouble, need help or advice, please contact us to schedule an appointment.

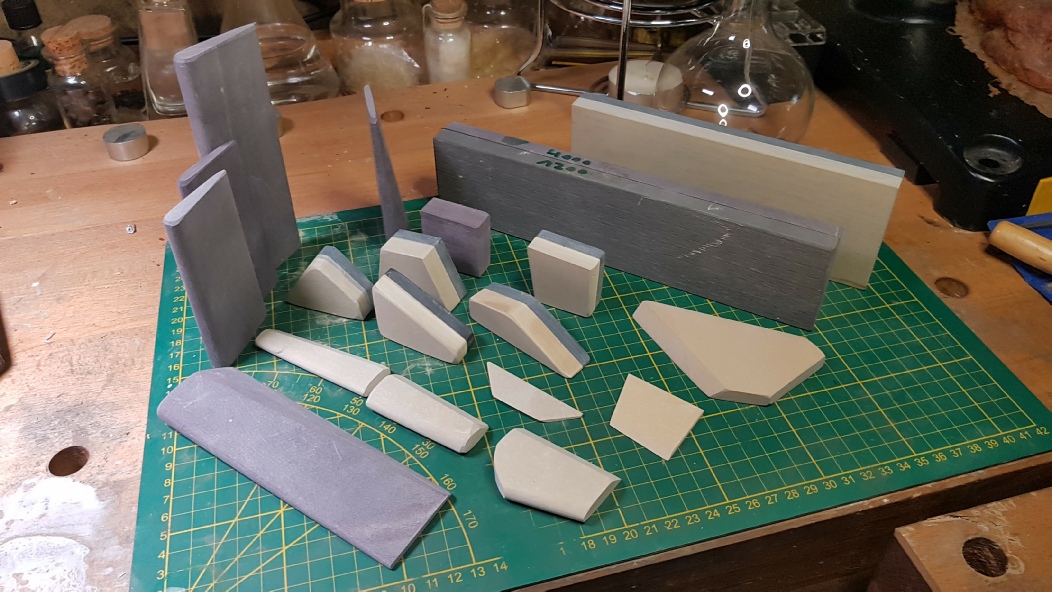

Verschillende metalen houtschaven

Wet grinder with 3 different leather polishing wheels on the left side, perfect for working on gouges.

Very small violin planes

Most common coarse whetstones

Grit 80, 100, 250

Grit 80, 100, 250

Learn how to attach a new leather strap to the polishing wheel without glue or sewing, and how to prevent it from coming loose later.

Leather polishing wheel for making gouges or hollow chisels ultra-sharp.

If your wet grinder can make it very smooth, you don't need a whetstone at all.

Discover the difference and learn how to coarsely or very finely adjust your wet grinder. Use

a leather polishing wheel, which comes with most wet grinders. With this technique, you no longer need a whetstone.

Ultra-sharpening is truly possible without special whetstones.

These days, you can also find very good and affordable wet grinders.

Most wet grinders are even cheaper than the expensive special whetstones.

You can even find affordable wet grinders that can rotate in both directions and have adjustable speeds.

Discover the difference and learn how to coarsely or very finely adjust your wet grinder. Use

a leather polishing wheel, which comes with most wet grinders. With this technique, you no longer need a whetstone.

Ultra-sharpening is truly possible without special whetstones.

These days, you can also find very good and affordable wet grinders.

Most wet grinders are even cheaper than the expensive special whetstones.

You can even find affordable wet grinders that can rotate in both directions and have adjustable speeds.

Coarse grit 80

Coarse grit 100 and 250

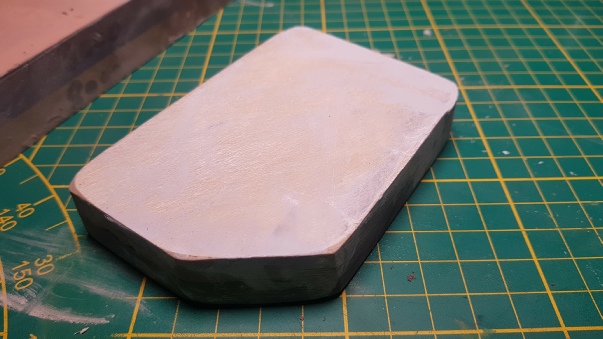

Compare the coarse grain and the fine stone…

Fine grit 3000 and 8000

Fine grit 1000 and 4000

Fine grit 8000

Fine grit 8000

Fine grit 8000

Large set of very fine whetstones, including some with a special shape for gouging.

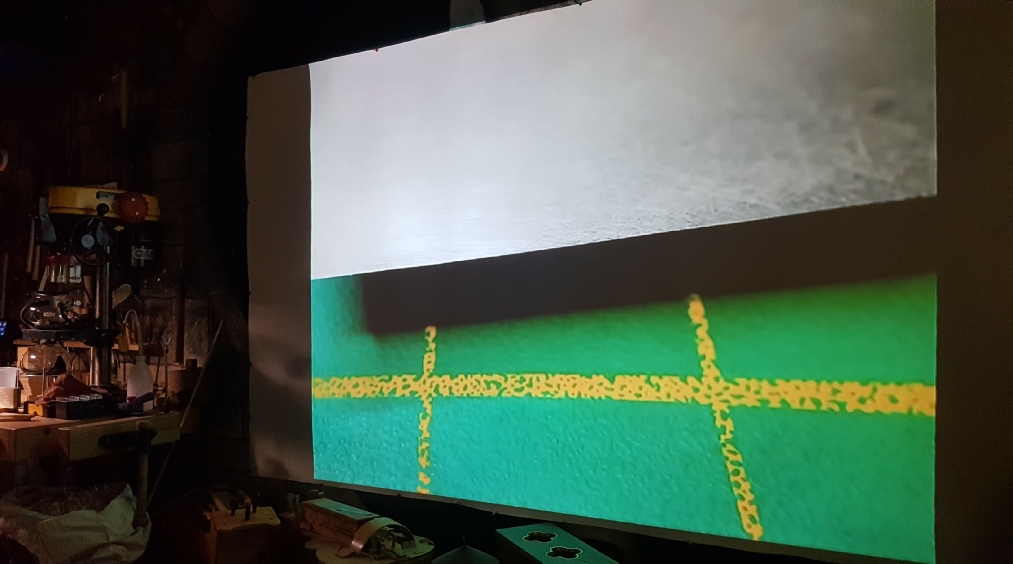

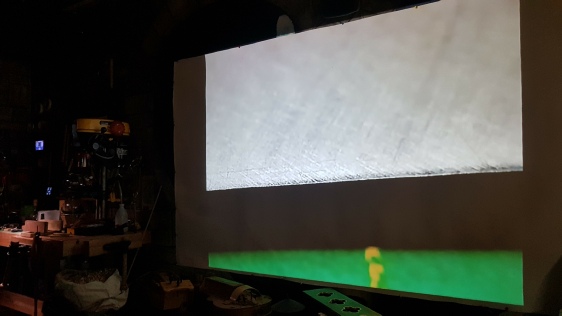

Hone and sharpen with a microscope.

This is helpful in the beginning to learn more about certain details.

A planer knife or chisel can be examined thoroughly under a microscope and projected onto a large screen.

Before and after sharpening/honing, checking for errors and defects...

In this photo below, small nicks on the cutting edge and many long vertical grooves/scratches can be seen.

You can't see them with the naked eye, and you can't feel them with your fingers either...

If you were to try to cut a sheet of paper with this knife, it would be a lot of hesitation, and the blade would tear repeatedly.

This is always the case when you hone with stones that are too coarse. The nicks/scratches always cause permanent nicks/burrs when you hone.

Your cutting edge will never be perfectly straight, but rather resemble a saw with a wavy line.

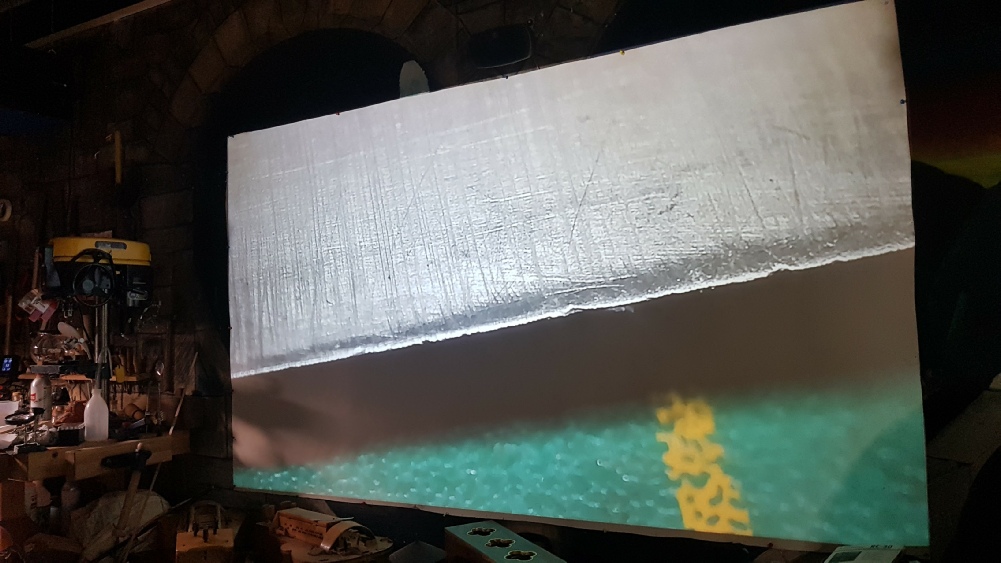

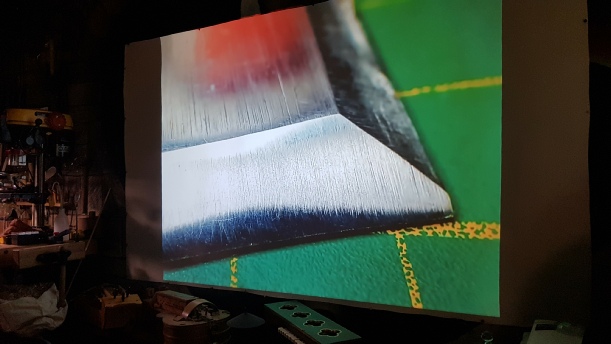

The flat side of the planer knife or chisel must first be polished completely flat and without scratches. Only then does grinding begin on the other side to create the beveled, concave side at the desired angle and in 1 facet.

This is helpful in the beginning to learn more about certain details.

A planer knife or chisel can be examined thoroughly under a microscope and projected onto a large screen.

Before and after sharpening/honing, checking for errors and defects...

In this photo below, small nicks on the cutting edge and many long vertical grooves/scratches can be seen.

You can't see them with the naked eye, and you can't feel them with your fingers either...

If you were to try to cut a sheet of paper with this knife, it would be a lot of hesitation, and the blade would tear repeatedly.

This is always the case when you hone with stones that are too coarse. The nicks/scratches always cause permanent nicks/burrs when you hone.

Your cutting edge will never be perfectly straight, but rather resemble a saw with a wavy line.

The flat side of the planer knife or chisel must first be polished completely flat and without scratches. Only then does grinding begin on the other side to create the beveled, concave side at the desired angle and in 1 facet.

Finish with fine grit 8000 or higher.

Before…

After...

Always plane the flat side of your flat chisel or plane knife first...

And remove any scratches by honing it with much softer whetstones...

And remove any scratches by honing it with much softer whetstones...

Grind a hollow bevel with a wet grinder in 1 facet.

Once hollow ground and deburred you get 3 facets…

The flat side of a chisel or planer blade, not visible to the naked eye…

Sharpening with a magnifying glass just makes things easier for you

and allows you to better monitor what you're doing.

and allows you to better monitor what you're doing.

Photos and text copyright Sascha Grimm (SasH Grimm)

To be continued...

Come back later.

Come back later.

Scrol down